Industrial Coffee Grinder: A Complete Guide for High-Volume Brewing

Industrial Coffee Grinder: A Complete Guide for High-Volume Brewing

Blog Article

Industrial Coffee Grinder Guide: Increase Efficiency and High Quality

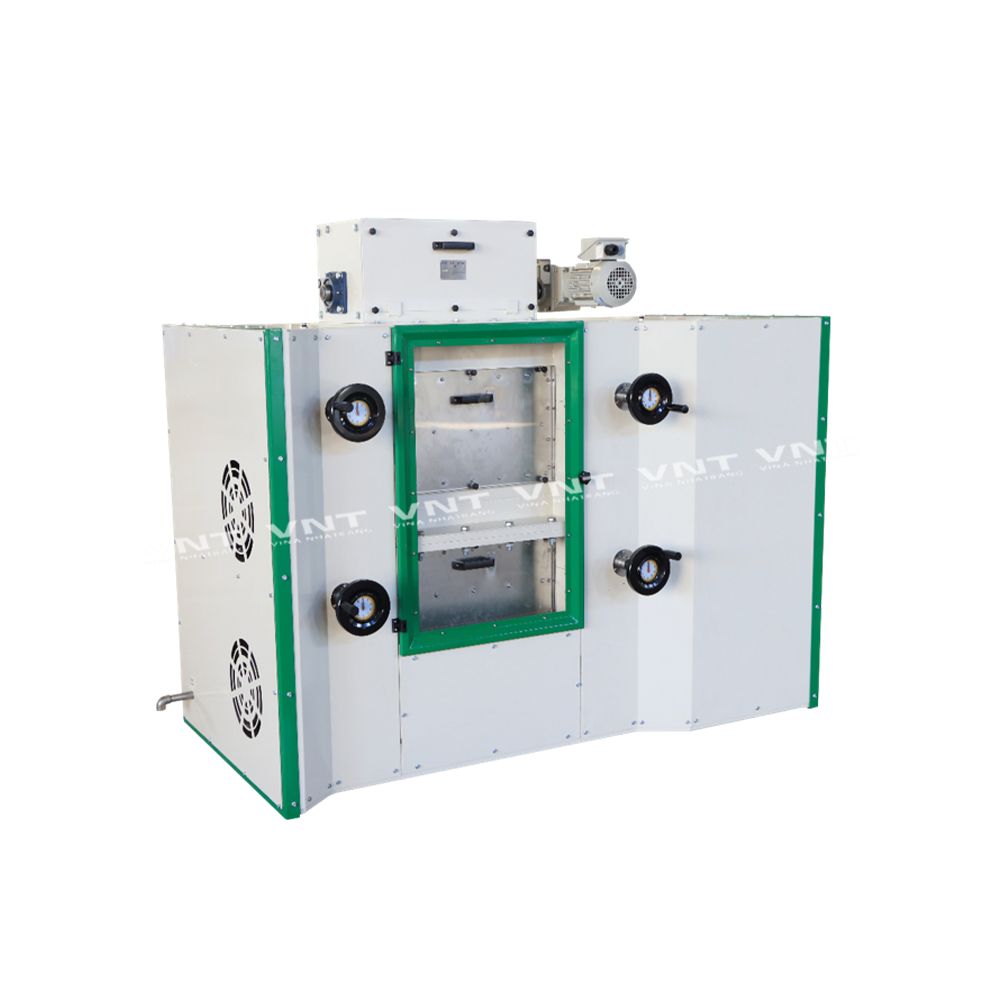

In the affordable landscape of coffee manufacturing, selecting the right industrial coffee grinder plays a critical function in improving both effectiveness and product high quality. Comprehending the nuances of different grinder types and essential features-- such as customizable grind settings and robust building-- can substantially influence the final taste profile of the coffee.

Comprehending Mill Kinds

When picking a commercial coffee grinder, understanding the numerous kinds readily available is important for optimizing both flavor removal and functional effectiveness. Both key kinds of grinders are blade grinders and burr mills. Blade grinders utilize sharp blades that cut coffee beans right into inconsistent dimensions, causing unequal extraction and possibly unfavorable flavors. While blade mills are usually a lot more appropriate and inexpensive for small-scale operations, they are usually not advised for industrial use.

Eventually, selecting the ideal kind of mill is important to preserving high quality and effectiveness in coffee production, making it critical for businesses to buy top quality burr mills for optimum results.

Key Functions to Take Into Consideration

Selecting an industrial coffee mill calls for careful consideration of a number of vital features that can considerably affect both efficiency and the total coffee experience. Among the primary aspects to examine is the grinding device. Burr mills are usually preferred over blade grinders, as they offer a constant work dimension, which is vital for optimum removal and taste.

Another important function is the grinder's capability. Depending upon the volume of coffee you need to process, select a version that can manage your needs without giving up rate or top quality. In addition, take into consideration the work setups used. A functional mill with several settings allows you to tailor the grind dimension to various developing techniques, improving the coffee's flavor profile.

The building and construction product likewise contributes in durability and upkeep. Stainless-steel components often offer long life and are much easier to clean up, which is important for keeping health standards. Lastly, review the grinder's noise degree, especially in an active coffee shop or production environment, where too much noise can be turbulent. Buying a mill that balances these functions can greatly boost both operational performance and the quality of the coffee offered.

Optimizing Grinding Refine

To achieve the finest outcomes in coffee prep work, maximizing the grinding procedure is important. The grind size substantially affects removal, taste, and total quality of the brewed coffee.

Furthermore, keeping an eye on the grinding speed can enhance the process. Slower grinding typically creates less heat, preserving delicate tastes and important site fragrances. Alternatively, much faster grinding might produce extreme heat, negatively impacting the coffee's quality.

Upkeep and Treatment Tips

Appropriate maintenance and care of commercial coffee mills great post to read are vital for making certain optimal performance and durability. Routine cleaning is the structure of upkeep; residue buildup can influence taste and grinding effectiveness. It is recommended to clean the mill after each usage, wiping down the outside and getting rid of any type of coffee grounds from the burrs.

In addition, check the grinding burrs for wear and tear. Dull burrs can compromise work consistency, so they should be changed as required. Industrial Coffee Grinder. Periodically adjusting the grinder is additionally critical, as this preserves the desired work size for numerous brewing approaches

Lubrication of relocating parts should be executed according to the producer's requirements, as this minimizes friction and extends the life of the equipment. It is crucial to utilize food-grade lubricants to make sure safety and compliance with health and wellness regulations.

Last but not least, keep the mill in a secure and dry atmosphere to stop corrosion and corrosion. By adhering to these upkeep and treatment suggestions, drivers can enhance the effectiveness of their commercial coffee grinders while making sure go to my site top quality outcome and expanded operational life.

Roi Evaluation

Evaluating the return on investment (ROI) for industrial coffee mills is critical for businesses seeking to enhance their coffee manufacturing capacities. A comprehensive ROI analysis aids establish the financial stability of purchasing premium grinders, enabling services to evaluate the preliminary expenses against prospective gains.

To carry out a detailed ROI analysis, companies ought to think about a number of essential elements. Evaluate the purchase price of the mill, including installation and any kind of essential adjustments to existing facilities. Next, compute functional expenses, including power usage, maintenance expenses, and labor performance enhancements. High-performance grinders frequently lead to lowered grinding time and boosted throughput, which can substantially improve performance.

Furthermore, take into consideration the influence on product high quality. Industrial Coffee Grinder. Superior grinders produce an even more constant work size, which can boost flavor accounts and customer contentment, eventually driving sales. By raising the high quality of the end product, services can justify higher rates, resulting in raised income

Final Thought

In recap, an industrial coffee grinder plays a pivotal function in improving both performance and product high quality within coffee manufacturing. By picking top notch burr grinders outfitted with important attributes such as flexible grind settings and long lasting construction, companies can make sure optimum flavor extraction. Moreover, normal upkeep is crucial for maintaining mill efficiency and taking full advantage of consumer satisfaction. Ultimately, the strategic investment in a reputable grinder contributes substantially to enhanced profits and competition in the coffee market.

In the competitive landscape of coffee production, picking the appropriate commercial coffee grinder plays a critical role in boosting both performance and product quality. The two key types of grinders are blade mills and burr mills. Within the burr grinder group, there are level burr grinders and conical burr mills, each with its advantages. Burr grinders are usually liked over blade grinders, as they offer a consistent grind dimension, which is vital for ideal extraction and taste.

In summary, a commercial coffee mill plays a pivotal duty in improving both efficiency and item high quality within coffee manufacturing.

Report this page